Labelling for the Industry 4.0: automation for smart factory

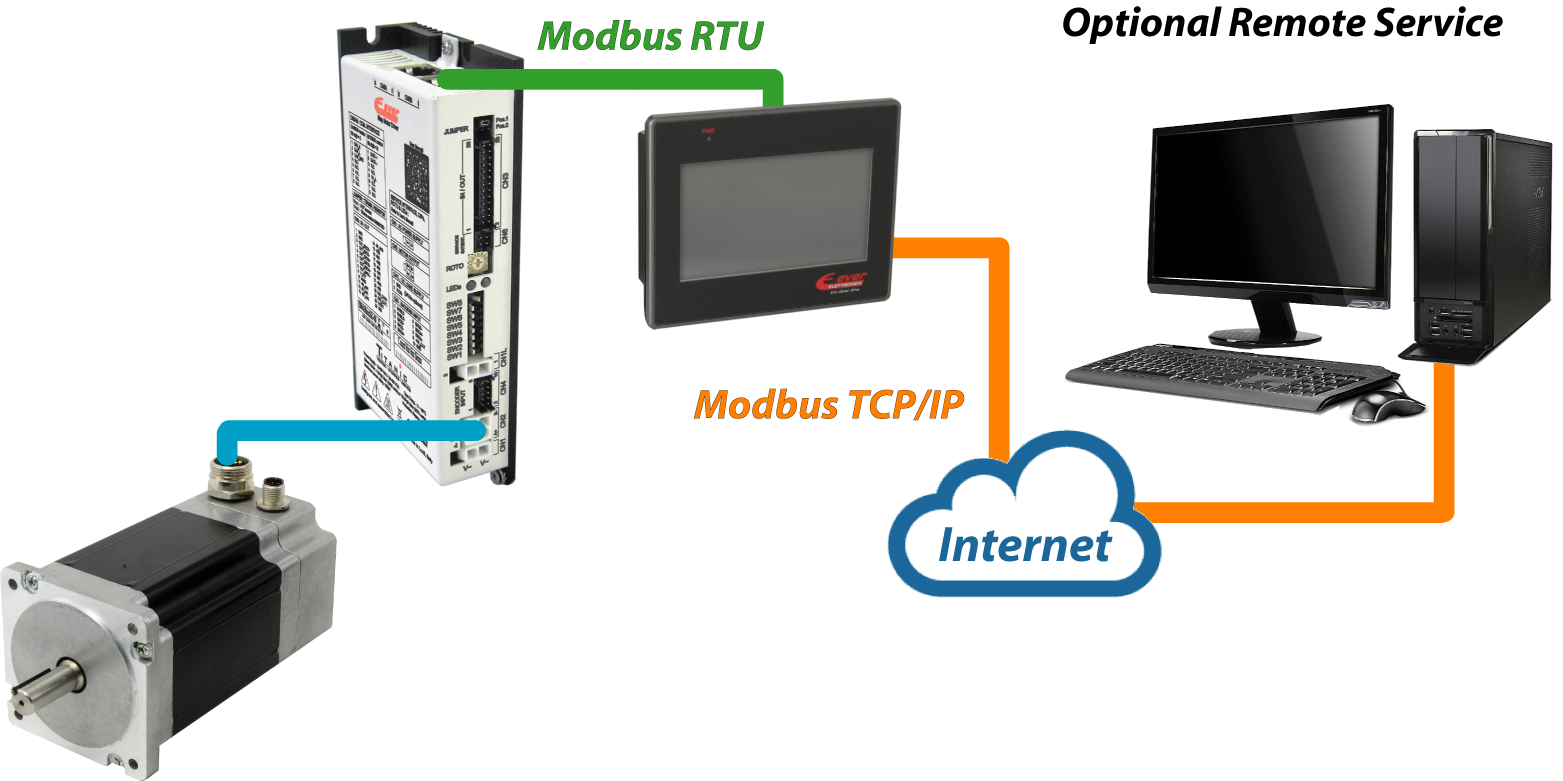

Ever Motion Solutions, oriented towards industry 4.0 and the smart factory, provides a ready-to-use single and multi-head labelling solution, based on : EtherCAT, Ethernet Modbus TCP/IP, CANopen and Profinet fieldbuses, applicable to the labelling device on a single head or multi head labelling machine and to all the accessory axes such as unwinder, rewinder, input belts, bottle rotation (3 rolls) and many others.

We provide a complete labelling solution, with programmable and versatile drive (for stepper motors and brushless motors) and with several systems sized according to requests (up to 200 m / min.).

The “labelling 4.0” solution for the smart factory is based on Titanio Series stepper drives and Vanadio Series AC brushless drives with Ethernet Modbus TCP/IP, EtherCAT, CANopen and Profinet fieldbuses. The Labelling Realtime Module, integrated into the e3PLC IDE Studio environment, allows a quick and easy start up and configuration of the labelling head.

Ever Motion Solutions technical assistance supports the customer during the start up phases and in the following evolutions of the application remotely or, when needed, directly at the customer's place.

Labelling Head Functionalities

- Main features of drives for stepper motors and brushless motors:

- Noiseless movement (stepless control)

- No step loss (closed loop feedback)

- Motor’s temperature reduction (stepper motors or brushless motors)

- Mains power supply 115-230 Vac

- Interfaceable with several fieldbuses: EtherCAT, Ethernet Modbus TCP/IP, CANopen and Profinet

- Label positioning error &alt; 0.5 mm

- Perfect synchronism between label speed/position and product speed/ position even with abrupts changes in product speed

- Label size available to automate the format change

- Double label function with different format label and counter-label with perfect adjustment of the two labels distance

- Missing label recovery with report of the label absence

- Software filters for the easy managing of special products and labels

- Easy customizations of the application to allow the management of several accessories such as: printing devices, printing control devices and pneumatic devices.

For the control of a single labelling head we provide a complete motion control solution with the software for stepper or brushless drives and HMI interface already programmed, but customizable.

For multi-head labelling control we provide a labelling control software already installed in the stepper or brushless drives. The PLC only needs to send the configuration parameters and provide supervision through EtherCAT, Ethernet Modbus TCP/IP, CANopen and Profinet fieldbuses.

The complete solution, available both in closed loop and in open loop, is composed of:

- Nema 34 stepper motors and AC brushless motors with an holding torque up to 10 Nm and with the possible addition of 5V encoder

- stepper drives and brushless drives with CE, Reach, RoHS and UL certifications.

Discover more about how we manage a labelling machine plates with our smart Industry 4.0 labelling solutions for the smart factory!